I thought about the layout together with the wooden board I bought last time. Previously, I mentioned the idea of hiding the rail underneath the board so that only the speaker would be visible on top. However, I am now reconsidering that approach. The atmosphere created by a minimal appearance versus a non-minimal one is clearly different, and I began to question whether minimality is truly necessary for this work. Therefore, after completing this prototype, I plan to build both versions, get feedback from myself and others, and decide how to proceed.

The reason I bring this up is nothing special; it is simply to say that this prototype will be built with the rail placed on top. Placing the rail itself is not a difficult task, but there is one very important thing that must be done: matching the height difference. The height of the motor—combined with its mounting bracket—is quite different from the height of the rail, and since the guide block moves by using the floor or the guide rail as support, the overall base height must be adjusted to support it. In other words, the rail must be higher than the motor, so additional layers need to be placed underneath to raise the height. This height difference was roughly 15mm. While I could match it, it didn’t look aesthetically pleasing, and adding that much wood simply translates to unnecessary weight, which kept bothering me.

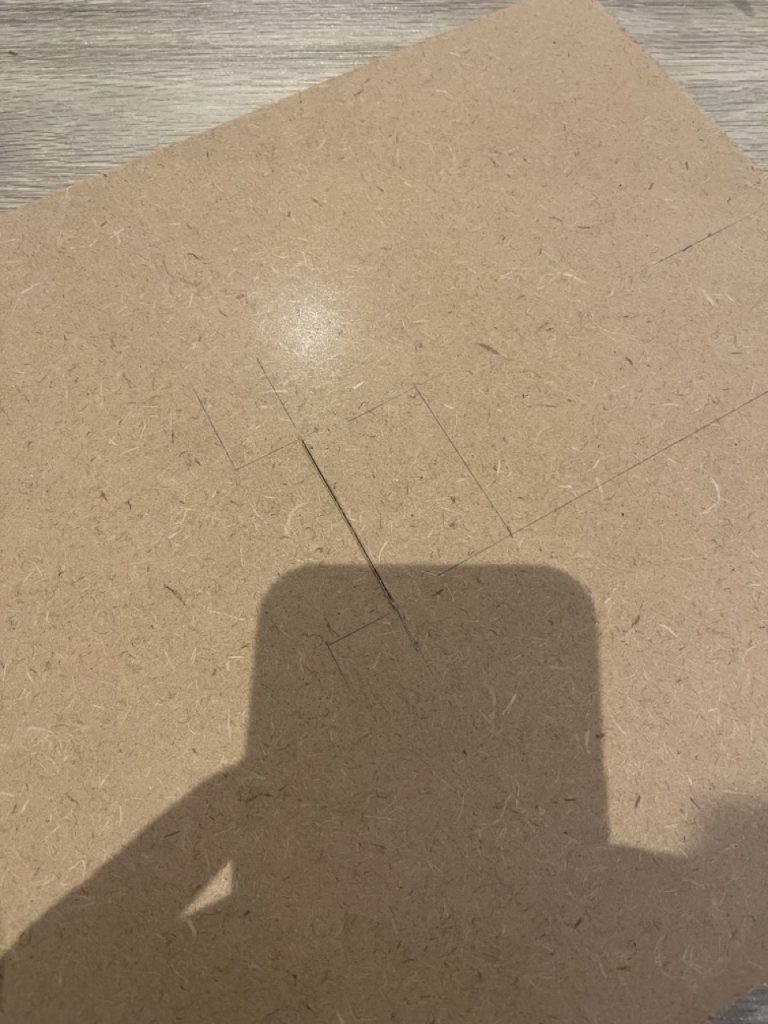

While thinking about this, I realized that the issue occurred because of the height between the motor and the motor bracket—and that solving just this would fix everything. Coincidentally, the thickness of the board I bought happened to be exactly right. So I came up with the idea of cutting out a hole that exposes only the front part of the motor bracket, and attaching the motor bracket under the wooden board. The problem is that the wood is too thick to cut a hole using only a craft knife. Therefore, I booked the 3D workshop for tomorrow and plan to use a cutter there to make the hole.

Tomorrow’s goal is to first create a hole on one side, check whether the motor fits well, confirm that there’s no issue with mounting, and ensure that the bolts don’t block the motor from fitting in. After that, I will create the hole on the other side. If I still have time afterward, I also plan to position the rail and do the drilling.