For this exhibition, the most crucial technical challenges will likely be the motor’s operation and thermal management. The motor needs to run continuously for 8-10 hours, and since the speakers must be driven while attached to a rail, thorough calculations and experiments regarding the load are deemed essential. This post aims to explore various methods for this purpose and detail an experiment on one of them.

Upon investigation, it’s clear that there are quite a variety of drive methods using motors and rails. To implement my idea, the speakers need to oscillate periodically along a fixed path, requiring a system involving a motor and linear motion. I believe that linear motors and pulleys with belts are the two main suitable methods for driving my artwork.

The pulley and belt system involves wrapping a belt around a motor and pulleys to create a defined path, then attaching an object to it for linear motion. This method can be constructed with inexpensive components and allows for fast operation, offering a wide range of achievable speeds. However, its disadvantages include lower stability and significant noise and vibration.

Linear motors can be further categorized into linear motors and screw linear motors. A linear motor functions similarly to a pulley and belt system, but the key difference is that it operates by magnetic force from an unrolled magnetic material. In simple terms, imagine an unrolled motor. This system provides more delicate and stable operation. However, it is expensive, and the cost increases exponentially with the length of the rail. It is primarily used in applications like 3D printers.

The second type is the screw linear. This system involves a motor rotating a screw rod, which then moves a plate attached to its axis. This method is stable and can withstand a relatively larger load compared to the belt pulley system. Its disadvantages include slight speed limitations and some noise and vibration, but these are considered to be at a very good level compared to the belt pulley method. Furthermore, it has the advantage of being configurable at a very reasonable price compared to the linear motor system. While it is more expensive than the belt pulley, it is an acceptable level.

Therefore, I decided to use the third method, the motor and screw linear system. For this, I ordered a motor, a motor driver, several connecting wires, a power supply, and a screw linear. Although there was a slight issue during the delivery of the screw linear, preventing its use during the initial experiment, I proceeded with testing the motor first, as combining them later would be straightforward.

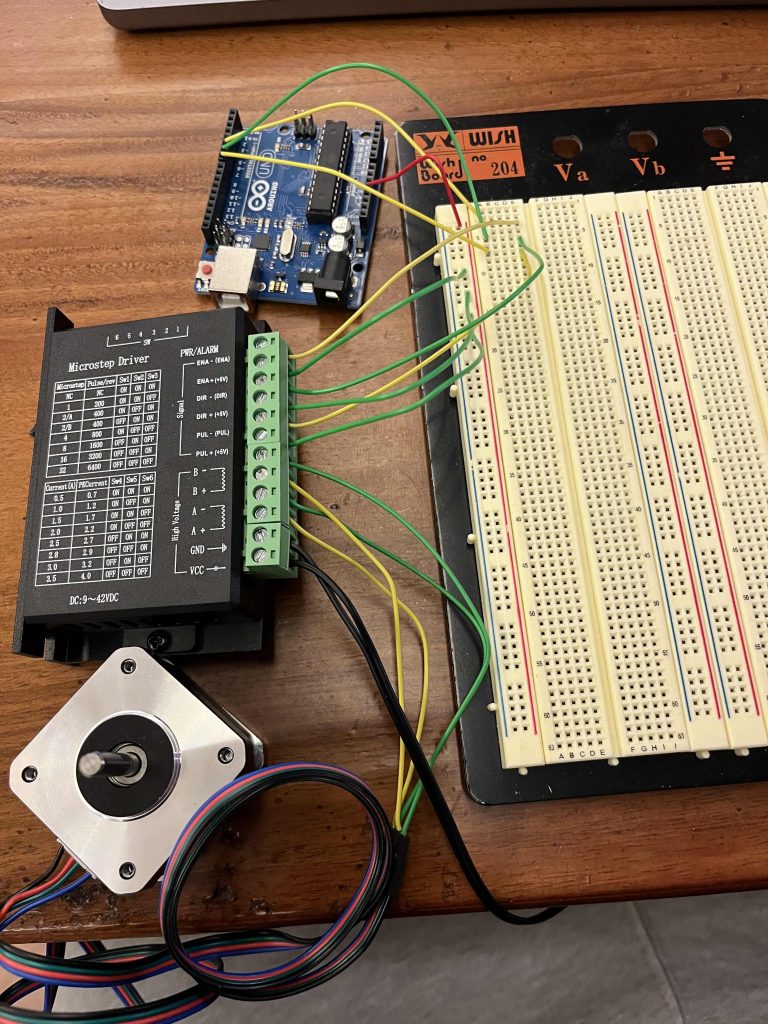

I used a low-speed motor. Motors come in various types and specifications, and I chose a low-speed motor that, while slow, can withstand a relatively large load. I used a NEMA 17 model, which is commonly employed in linear motion systems like this. To drive the motor, a motor driver capable of receiving power and signals is necessary, so I used a TB6600 driver. The motor’s rated voltage was 12V and rated current was 0.4A, so I used a 12V 2A power supply. An Arduino was used to send signals to the motor via a computer. The connection method referred to a diagram found online.

To use the driver’s DIR, PUL, and ENA pins, separate power needed to be supplied, and they had to be used in a pull-up configuration. So, I supplied power using the Arduino’s 5V pin, and the motor’s power was supplied through a power adapter. The code was set to make the motor rotate in the forward direction for 6400 steps, and then rotate in the reverse direction for another 6400 steps.

The experiment was successful, and the motor rotated stably. However, whether the speaker will undergo constant velocity motion or accelerated motion is unknown. Therefore, next time, I need to consider coding for accelerated motion while operating the screw linear. Additionally, since the screw linear has a defined operational range, I will also need to find a method to calculate the number of motor rotations to match that length.